Sumerian Bronze & Alloy Calculator with demo examples eTCL numerical analysis

Sumerian Bronze & Alloy Calculator with demo examples eTCL numerical analysis

This page is under development. Comments are welcome, but please load any comments in the comments section at the bottom of the page. Please include your wiki MONIKER and date in your comment with the same courtesy that I will give you. Aside from your courtesy, your wiki MONIKER and date as a signature and minimal good faith of any internet post are the rules of this TCL-WIKI. Its very hard to reply reasonably without some background of the correspondent on his WIKI bio page. Thanks, gold 12Dec2018

- Sumerian Bronze & Alloy Calculator with demo examples eTCL numerical analysis

- Introduction

- Appendix Code

- Hidden Comments Section

Introduction

gold Here is some eTCL starter code for calculating ratios of bronze and other alloys from Sumerian texts and excavations. The impetus for these calculations was checking prices in some cuneiform texts and modern replicas. Most of the testcases involve replicas or models, using assumptions and rules of thumb.

Ratios of copper/tin for bronze alloys

For a testcase from Elba text TM75G1310, 5+30/60 minas of copper and 40/60 minas of tin were combined to form a bronze alloy. The smelter loss was estimated to be 70 shekels,70/60, 1.166 rounded minas. The alloy ratio was (5+30/60)/(40/60),5.5/0.666, or 8.25 from the hand calculator. The eTCL calculator returned an alloy ratio of 8.258. The trial formula for smelter product was (5+30/60)+(40/60)-1.166, 5.0006 minas. The eTCL calculator returned an alloy mass of 5. rounded minas. Additional decimal points here are used to check the calculator results and are not inferences on the text accuracy.

The Mari text TM7 recorded an instance where 8 minas of copper and 1/3 minas of tin were combined. The alloy ratio was 8/(1/3) or 24.02 from the hand calculator. The eTCL calculator returned an alloy ratio of 24.024. The smelter loss could not be inferred from the text.

An Akkadian text indicated that an alloy ( billatu) was made of 1 mina of copper and 8+1/2 shekels of tin . The alloy ratio was (1.*60.)/(8.5), 60./8.5, or 7.0588 from the hand calculator. The eTCL calculator returned an alloy ratio of 7.058.

From an Old Assyrian text, 4 minas of copper and 1/2 mina of tin were combined. The alloy ratio was 4./0.5, (4.*60.)/(.5*60.), or 8. from the hand calculator. The eTCL calculator returned an alloy ratio of 8.0.

In the text TM75G1310 from Elba, 30 minas of copper and 3 minas 20 shekels of tin were mixed to form a copper tin bronze. The alloy product was 2000 shekels of bronze, 2000/60, or 33.33 minas. The alloy ratio was 30/(3+20/60),30/3.333, or 9 from the hand calculator. The eTCL calculator returned an alloy ratio of 9.009. From figures in the text, the smelter loss was 30+(3+20/60)-33.33, 0.0033. The trial formula for smelter product was 30+(3+20/60)-0.0033, 33.33, rounded minas. The eTCL calculator returned an alloy mass of 33.326 , rounded. For the trial formulas, the metal prices from the UrIII era will be used (mixing countries and eras). From the UrIII Equivalency lists, the silver price was 1 silver shekel for 90 shekels of copper and the tin price was 1 silver shekel for 15 to 20 shekels of copper (UrIII). Using proportions, the copper value was (30*60)*(1/90), 20 silver shekels. The tin value was (3.33*60)*(1/20), 9.99, rounding 10 silver shekels.

Nagga metal and prices

A word search on the CDLI library show a number of hits for the Su. nagga metal, including prices in UrIII. Some Sumerian translations carry nagga as lead and some translations as tin. The words Su. nagga and Akk. anakku (tin) may be related phonetically. The Su. nagga may be a shortening of na-ga-su-ra (foreign stone or mountain stone). Sanskit has associated Sk. naga with lead, which lends to the interpretation of nagga as lead. Also, sometimes the phrase ge4 nagga (black nagga) occurs in some texts, which would be a characteristic of lead. The CDLI texts showed the nagga metal was valued at 14 to 20 shekels to a shekel of silver. One tablet Ashm1911-0240 has the phrase nagga-bi 10+4+(1/2) gin-ta. Since gin-ta is a Sumerian phrase meaning (in context) its rate in silver, the conversion to decimal 14.5 shekels is the direct price in silver. Another tablet Erm14969 has 2 manas of nagga valued at 8 gin of silver, which converts to (2*60)/8 or 15 shekels of nagga metal per shekel of silver. One text P113273 has 4 manas of nagga metal valued at 12 shekels of silver, which gives a rate of (4*60)/12 or 20 shekels per 1 silver shekel. Another text MLC02600 has 1 mana nagga metal its silver 5 gin, which converts to (1*60)/5 or 20 shekels per 1 silver shekel.

Continuing with the searches of the word nagga metal in the CDLI library, there are several phrases that have (quantity) mana nagga zabar in the transliterations. Conventionally, nagga means lead or tin and zabar means copper tin bronze. At this point, the research cannot rule out nagga as tin. Possibly nagga zabar is a tin/copper alloy of some kind.

The tablet BCT289 = 1982A1098 gives tallied weights of refining and melting copper, combining copper with some other metal. While the Umma ( UrIII ) tablet has unreadable lines and not completely understood, an average figure for the refining losses can be derived from the copper weight and losses. The term refining losses is used here, since the circumstances probably indicates a melting furnace or crucible using refined or reused copper, not smelting copper ore which would produce a large amount of slag. For the three firings by separate smiths, each copper charge issued was 27+2/3 minas plus 5 shekels of copper and suggested the melting furnace or crucible copper capacity of 28 minas or 14 kilograms rounded. The first refining loss was (1+18.5/60)/(27+1*(2/3)+5/60), 0.04714, 4.714 percent. The second refining loss was (1+18/60)/((27+2/3)+5/60), 0.04686, 4.6846 percent. The third refining loss was partly unreadable, but appears similar to the previous two, (1+18/60)/((27+2/3)+5/60), 0.04686, 4.6846 percent. The average refining loss over three forgings was (4.714 + 4.6846+4.6846)/3, 4.6944, rounded 4.7 percent. Since there are other Sumerian texts which cite copper reuse, refining losses, and input/product mass mismatchs, where forging copper only, it is advantageous to estimate the average refining loss in the UrIII forges.

Ratios and metal prices

The gist of tablet E118 gives two prices of suhe substance in year Su-Suen 1. The price of suhe substance was (1+1/3) minas over (1+1/3) gin, converting ((1+1/3)*60)/ (1+1/3) , 60 shekels of suhe metal per 1 silver shekel. The price of suhe substance was 14 gin over igi-4 (1/4???) gin, converting (14)/ (1/4) , 56 shekels of suhe metal per 1 silver shekel.

The gist of tablet E59431 gives weights of sets of old copper sickles turned into an Umma warehouse under year Shulgi 47. The average weight of the old sickles can be estimated with the hand calculator. The average weight of 4 old sickles was (12+1/3) minas over 114 sickles, converting ((12+1/3)*60)/114, /114, decimal 6.49 gin. The average weight of 4 old sickles was (1/2) minas over 4 sickles, converting ((1/2)*60)/4, 30/4, decimal 7.5 gin. The average weight of 20 old sickles was 3 minas over 20 sickles, converting (3*60)/20, 180/20, decimal 9.0 gin. The fourth set of old sickles on the tablet were mostly unreadable. For comparison with new sickles, the two tablets, BCT2=86=1982A1096 and BCT2=86=1982A1096, rated a light barley sickle at 12 gin and a heavy sickle at 15 gin. The association with pick-axes suggests that the heavy sickle might have been used for cutting brush and clearing land. The translations cited "hammered work" on both tablets.

In the eTCL calculator, kilograms are used with the price ratios of copper (1/90) and tin (1/20) for UrIII. From the trial calculations, these price ratios were transferred correctly to kilograms of silver. The price table contains redundant entries from different texts. However, the trade values or price ratios were undoubtedly different in different eras, countries, and texts.

Pseudocode and Equations

Sumerian price in silver = [/ liters 300.] Sumerian price in liters grain = [* silver 300.] # 1 silver piece = 1 gur = 300 liters of grain liters = [* volume_in_cubic_cm .001] original copper mass + original tin mass - product mass = smelter loss original metal mass - product mass = smelter loss original metal mass * average refining loss in percent= refining loss original metal mass - refining loss = product mass 30 to 40 kg of charcoal for 1 kg of copper, rule of thumb (for smelting copper in raw ore) original metal mass * price ratio in silver 1/N = price in silver 6 bundles or 60 kgs of reeds for 1/2 mana of copper, rule of thumb 120 manas or 60 kgs of reeds for 1/2 mana of copper, rule of thumb bundle of reeds was 20 manas or 10 kg price? = raw materials + labor + profit price? = raw materials + heat process price? = raw materials + labor average price per unit = revenue / units sold

Table 1 , UrIII Prices

| UrIII Metal prices | per silver shekel etc | country, era |

|---|---|---|

| quantity | value | comment, if any |

| copper | 3 minas= 180 shekels | Babylon, Esnunna Code prices, 1900 BCE, for comparison |

| copper | 1.5 minas= 90 shekels | NeoSumerian, UrIII, circa 2300 BCE |

| copper | 80 shekels | NeoSumerian, UrIII, circa 2300 BCE |

| tin | 12 shekels | NeoSumerian, UrIII, circa 2300 BCE |

| tin | 20 shekels | NeoSumerian, UrIII, circa 2300 BCE |

| red gold | 15 shekels | NeoSumerian, UrIII, circa 2300 BCE |

| gold | 7 shekels | NeoSumerian, UrIII, circa 2300 BCE |

| gold | 20 shekels | NeoSumerian, UrIII, circa 2300 BCE |

Table 2 , OB Prices

| O.B. Metal prices | per silver shekel etc | country, era |

|---|---|---|

| quantity | value | comment, if any |

| iron | 8 shekels | Southern Mesopotamia, Old Babylonian period |

| iron | 12 shekels | Mari, Old Babylonian period |

| iron | 40 shekels | Assur, Old Babylonian period |

| gold | 3-6 shekels | Southern Mesopotamia, Old Babylonian period |

| gold | 4-6 shekels | Mari, Old Babylonian period |

| gold | 4-8 shekels | Assur, Old Babylonian period |

Table 3 , Price and Exchange ratios

| Metal price ratios | for comparison | country, era |

|---|---|---|

| quantity | value | comment, if any |

| silver/gold price | 10:1 | NBC6641,NeoSumerian, UrIII, circa 2200BCE |

| silver/gold price | 10.2:1 | Yale YBC13418A,NeoSumerian, UrIII, circa 2200BCE |

| copper/silver price | 9:1 | Ancient Egypt, New Kingdom |

| tin/copper price | 6.6:1 | Athens, Greece, circa 500BCE |

| silver/gold exchange ratio | 12:1 | Ancient Rome, Augustus reign, 30BCE |

| silver/gold exchange ratio | 13:1 | Persian empire, 300 BCE |

| silver/gold exchange ratio | 15:1 | US Coinage Act of 1792 |

| silver/gold exchange ratio | 16:1 | US Coinage Act of 1834 |

Testcases Section

In planning any software, it is advisable to gather a number of testcases to check the results of the program. The math for the testcases can be checked by pasting statements in the TCL console. Aside from the TCL calculator display, when one presses the report button on the calculator, one will have console show access to the capacity functions (subroutines).

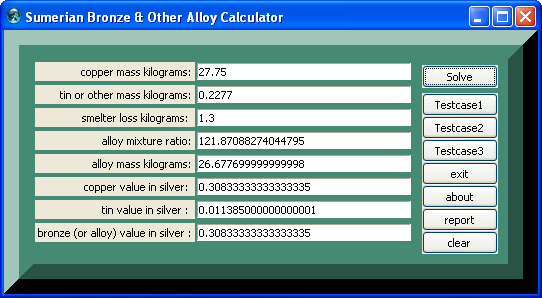

Testcase 1

| table 1 | printed in | tcl wiki format |

|---|---|---|

| quantity | value | comment, if any |

| testcase number: | 1 | |

| copper mass kilograms: | kilograms | 27.75 |

| tin mass kilograms: | kilograms | 0.2277 |

| alloy mass kilograms : | set | 1.3 |

| metal alloy ratio : | no units | 121.870 |

| alloy mass: | kilograms | 26.677 |

| copper value in silver : | kilograms | 0.308 |

| alloy value in silver : | kilograms | 0.0113 |

Testcase 2

| table 2 | printed in | tcl wiki format |

|---|---|---|

| quantity | value | comment, if any |

| testcase number: | 2 | |

| copper mass kilograms: | kilograms | 27.75 |

| tin mass kilograms: | kilograms | 0.225 |

| alloy mass kilograms : | set | 1.3 |

| metal alloy ratio : | no units | 123.333 |

| alloy mass : | kilograms | 26.675 |

| copper value in silver : | kilograms | 0.308 |

| alloy value in silver : | kilograms | 0.011 |

Testcase 3

| table 3 | printed in | tcl wiki format |

|---|---|---|

| quantity | value | comment, if any |

| testcase number: | 3 | |

| copper mass kilograms: | kilograms | 25.00 |

| tin mass kilograms: | kilograms | 0.25 |

| alloy mass kilograms : | set | 1.5 |

| metal alloy ratio : | no units | 100.0 |

| alloy mass : | kilograms | 23.75 |

| copper value in silver : | kilograms | 0.277 |

| alloy value in silver : | kilograms | 0.0125 |

Testcase 4

Model Copper / Bog Iron Furnace

| table 4 | printed in | tcl wiki format |

|---|---|---|

| quantity | value | comment, if any |

| testcase number: | 4 | |

| bloomery diameter meters: | .75 | |

| bloomery height meters: | .7 | |

| bloomery firing seconds: | 216000. | |

| volume cubic meters: | 0.309 | |

| total energy MJ: | 1095.700 | |

| bloomery volume m*m*m: | 0.309 | |

| bloomery temperature. | degrees. centigrade, | |

| exp. model temp. | 1100 | |

| max room fuel kg | 262.862 | |

| estimated fuel,charcoal kg | 35.924 | |

| total heat megajoules | 1095.700 | |

| firing max temperature | 1098 | |

| man workdays to load fuel | 0.103 | |

| fuel to ore ratio | 1:1 | |

| bloomery metal product kilograms | 10kg | bloom of prils and slag broken off and hammered |

Screenshots Section

figure 1.

References:

- Cuneiform Collection of the

- Peabody Essex MuseumCuneiform Digital Library Journal 2012:1, Xiaoli Ouyang and W. R. Brookman

- [L1 ]

- Lading of the late bronze age ship at uluburun,thesis, may 2003, shih-han samuel lin

- Transition from Bronze to Iron in the Near East, Carlo Zaccagnini,Sep 1990

- Sources of Tin and the Beginnings of Bronze Metallurgy, James D. Muhly

- Significance of Tin in Turkish Mining, Ergun Kaptan

- Trade in and metal sources for the Indian Bronze Age, J.van Hoorn

- Oxhide ingots, copper production, trade, thesis,michael rice jones,2007

- Robert Englund, UCLA [L2 ]

- Ur III Tablets in the Valdosta State University, search on cdli

- Cuneiform Digital Library Journal, search on Equivalency Values

- Ur III Equivalency Values[L3 ]

- Especially, the Ur III Equivalency Values for copper & silver sections.

- The Sumerian keywords search on the cdli

- are very effective, but major size files to download

- Oxhide_ingot [L4 ]

- Uluburun_shipwreck [L5 ]

Appendix Code

appendix TCL programs and scripts

# pretty print from autoindent and ased editor

# Sumerian bronze alloy calculator

# written on Windows XP on eTCL

# working under TCL version 8.5.6 and eTCL 1.0.1

# gold on TCL WIKI, 15sep2014

package require Tk

namespace path {::tcl::mathop ::tcl::mathfunc}

frame .frame -relief flat -bg aquamarine4

pack .frame -side top -fill y -anchor center

set names {{} {copper mass kilograms:} }

lappend names {tin or other mass kilograms:}

lappend names {answers: average refining loss kilograms: }

lappend names {alloy mixture ratio:}

lappend names {alloy mass kilograms:}

lappend names {copper value in silver: }

lappend names {tin or other value in silver : }

lappend names {bronze (or alloy) value in silver :}

foreach i {1 2 3 4 5 6 7 8} {

label .frame.label$i -text [lindex $names $i] -anchor e

entry .frame.entry$i -width 35 -textvariable side$i

grid .frame.label$i .frame.entry$i -sticky ew -pady 2 -padx 1 }

proc about {} {

set msg "Calculator for Sumerian Bronze

& Other Alloy from TCL WIKI,

written on eTCL "

tk_messageBox -title "About" -message $msg }

proc calculate { } {

global answer2

global side1 side2 side3 side4 side5

global side6 side7 side8

global testcase_number

incr testcase_number

set copper1 [* $side1 1. ]

set tin1 [* $side2 1. ]

set loss1 [* $side1 4.7 0.01]

set side3 $loss1

set side4 [/ $copper1 $tin1 ]

set side5 [- [+ $copper1 $tin1 ] $loss1 ]

set side6 [* $copper1 [/ 1. 90.] ]

set side7 [* $tin1 [/ 1. 20. ] ]

set side8 [* $copper1 [/ 1. 90.] ] }

proc fillup {aa bb cc dd ee ff gg hh} {

.frame.entry1 insert 0 "$aa"

.frame.entry2 insert 0 "$bb"

.frame.entry3 insert 0 "$cc"

.frame.entry4 insert 0 "$dd"

.frame.entry5 insert 0 "$ee"

.frame.entry6 insert 0 "$ff"

.frame.entry7 insert 0 "$gg"

.frame.entry8 insert 0 "$hh"

}

proc clearx {} {

foreach i {1 2 3 4 5 6 7 8 } {

.frame.entry$i delete 0 end } }

proc reportx {} {

global side1 side2 side3 side4 side5

global side6 side7 side8

global testcase_number

console show;

puts "%|table $testcase_number|printed in| tcl wiki format|% "

puts "&| quantity| value| comment, if any|& "

puts "&| testcase number:| | $testcase_number|&"

puts "&| copper mass :|kilograms | $side1 |&"

puts "&| tin (or other) mass :|kilograms | $side2|& "

puts "&| average refining loss :|kilograms|$side3|& "

puts "&| alloy mixture ratio :| no units|$side4 |&"

puts "&| alloy mass :| kilograms|$side5 |&"

puts "&| copper value in silver :| kilograms|$side6 |&"

puts "&| tin value in silver :| kilograms|$side7 |&"

puts "&| bronze (or alloy) value in silver :| kilograms|$side8 |&"

}

frame .buttons -bg aquamarine4

::ttk::button .calculator -text "Solve" -command { calculate }

::ttk::button .test2 -text "Testcase1" -command {clearx;fillup 27.75 0.2277 1.3 121.18 26.6 0.308 .011 0.308}

::ttk::button .test3 -text "Testcase2" -command {clearx;fillup 27.75 0.225 1.3 123.3 26.675 0.308 0.011 0.308 }

::ttk::button .test4 -text "Testcase3" -command {clearx;fillup 25.00 0.25 1.5 100.1 23.75 0.277 0.0125 0.277 }

::ttk::button .clearallx -text clear -command {clearx }

::ttk::button .about -text about -command about

::ttk::button .cons -text report -command { reportx }

::ttk::button .exit -text exit -command {exit}

pack .calculator -in .buttons -side top -padx 10 -pady 5

pack .clearallx .cons .about .exit .test4 .test3 .test2 -side bottom -in .buttons

grid .frame .buttons -sticky ns -pady {0 10}

. configure -background aquamarine4 -highlightcolor brown -relief raised -border 30

wm title . "Sumerian Bronze & Other Alloy Calculator "

Pushbutton Operation

For the push buttons, the recommended procedure is push testcase and fill frame, change first three entries etc, push solve, and then push report. Report allows copy and paste from console.

For testcases in a computer session, the eTCL calculator increments a new testcase number internally, eg. TC(1), TC(2) , TC(3) , TC(N). The testcase number is internal to the calculator and will not be printed until the report button is pushed for the current result numbers. The current result numbers will be cleared on the next solve button. The command { calculate; reportx } or { calculate ; reportx; clearx } can be added or changed to report automatically. Another wrinkle would be to print out the current text, delimiters, and numbers in a TCL wiki style table as

puts " %| testcase $testcase_number | value| units |comment |%" puts " &| volume| $volume| cubic meters |based on length $side1 and width $side2 |&"

gold12Dec2018. This page is copyrighted under the TCL/TK license terms, this license .

Hidden Comments Section

Please place any comments here with your wiki MONIKER and date, Thanks.gold12Dec2018

AMG: In this wiki, [single brackets] are links to other pages. If you don't want to link but just want brackets to show up in the displayed page, use [[double brackets]] instead.

| Category Numerical Analysis | Category Toys | Category Calculator | Category Mathematics | Category Example | Toys and Games | Category Games | Category Application | Category GUI |